At Hikari, we stand at the forefront of sewing machine manufacturing, leveraging the finest equipment and adopting world-class internal management tools to cater to future development demands.

At Hikari, we stand at the forefront of sewing machine manufacturing, leveraging the finest equipment and adopting world-class internal management tools to cater to future development demands. One of the industry's few centers equipped with state-of-the-art precision machining technology, achieving an impressive accuracy of 2 micrometers, equivalent to just 1/35th of a human hair's thickness.

One of the industry's few centers equipped with state-of-the-art precision machining technology, achieving an impressive accuracy of 2 micrometers, equivalent to just 1/35th of a human hair's thickness. We strictly control every component, relying on a supply chain comparable to the world's leading brands.

We strictly control every component, relying on a supply chain comparable to the world's leading brands.

Our CNC machining workshop plays a vital role in the production of sewing machine parts. Equipped with 25 machining centers, including 13 from the prestigious Japanese Okuma brand, we achieve an accuracy of 0.002 millimeters. These sophisticated machines, typically used for precision parts in the automotive and aviation industries, are now instrumental in manufacturing our high-end sewing machines, setting us apart in the industry.

Our primary mission is to create high-performance products that cater to the high-end market. With a firm focus on maintaining equipment stability and minimizing vibration-related issues, we invested significantly in constructing a solid foundation. Our factory floor boasts reinforced concrete, with a remarkable thickness of 1.5 meters, surpassing even the standards of airport runways (typically 0.5-0.75 meter), ensuring seamless operations and high performance of our advanced machinery.

Step into our automated sewing unit manufacturing workshop, where each machine is meticulously assembled following a strict and scientific production sequence. At every stage, our skilled workforce adheres to detailed guidelines outlined in the work standards, ensuring precise assembly and high-quality production. Through self-inspections, mutual inspections, and stringent controls of critical stages, we guarantee the high quality of products. Comprehensive testing and analysis, right from the initial assembly to the final product packaging, are efficiently conducted before the final storage using the SAP system.

This finished product assembly workshop houses the revolutionary Hikari 8800, the world's first computerized automatic oil supply direct-drive lockstitch machine. With ten production lines in operation, we achieve an annual output of up to 300,000 units.

This workshop boasts a state-of-the-art fully automated conveyor system, complemented by AGV (Automated Guided Vehicle) robots, significantly reducing manual labor intensity. We have embraced automation and intelligent technologies, transforming our production process into an efficient and smart factory, paving the way for the future of sewing industries.

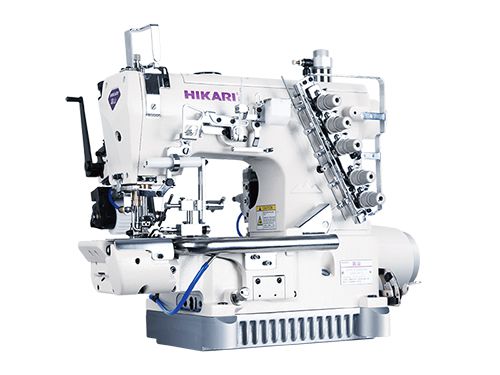

In the second assembly workshop, we focus on creating products such as the groundbreaking Hikari 6800TD direct-drive computerized overlock sewing machine, the 688T Cloud Series, and the Hikari 782, 762, and 800 direct-drive computerized automatic thread cutting interlock sewing machines.

With nine production lines in operation, we deliver up to 180,000 units annually. Our substantial investment in conveyor systems and AGV technology ensures seamless transportation and assembly of machines based on real-time order quantities, further elevating our capabilities in smart manufacturing.